Api 650 Tank Construction Sequence / API 650 Tanks | Gpi Tanks & Process Equipment : Advance tank has extensive experience with api 650 tanks ranging.

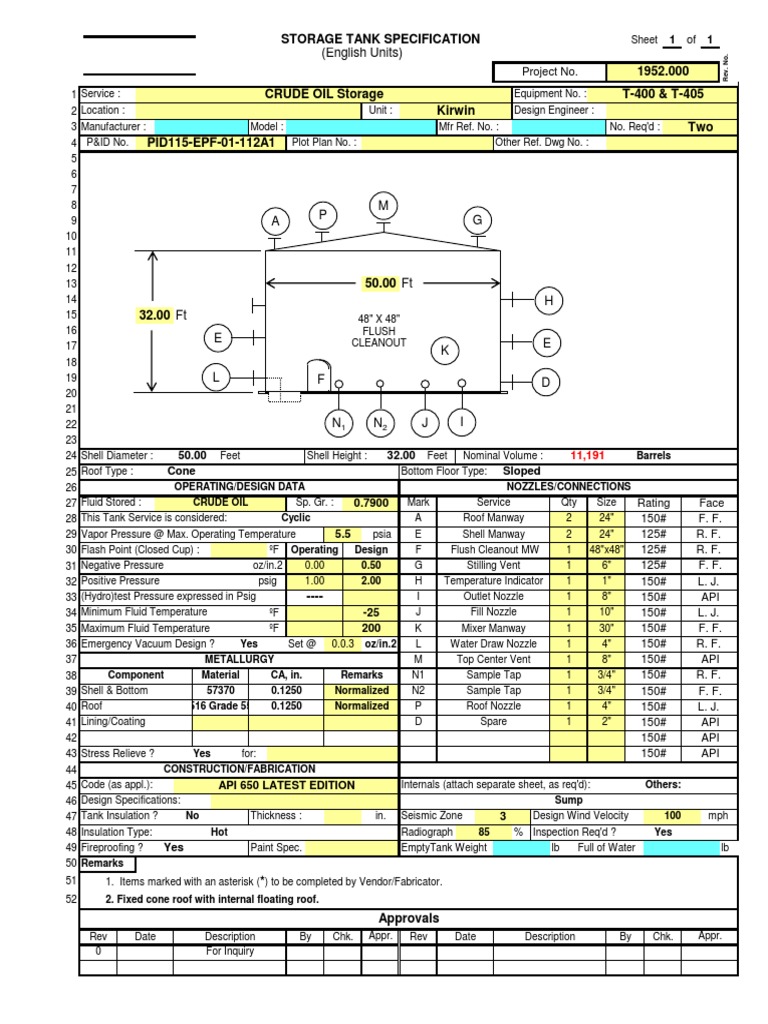

Api 650 Tank Construction Sequence / API 650 Tanks | Gpi Tanks & Process Equipment : Advance tank has extensive experience with api 650 tanks ranging.. After being laid out and tacked, bottom plates shall be joined by welding the joints in the sequence provided in attachment 2, unless otherwise specified by the engineer. Depending on the desired design and design conditions, these tanks are equipped with a conical roof or a doomed roof, with or without anchors and stiffening. Tank design detailing introduction the api 650 standard is designed to provide the petroleum industry with tanks of adequate safety and reasonable economy for. This standard does not present or establish a fixed series of allowable tank sizes; These storage tanks operate at 250°f or less with an.

In api 650 (welded steel tanks for oil storage ) we usually use lap joint and the examination please refer to para 7.3.3 selama pekerjaannya sudah sesuai sequence saya pikir tidak akan ada masalah. Advance tank has extensive experience with api 650 tanks ranging. The api specifications address the required thickness of each piece of steel based on the size of the tank being built as well as the welding requirements. The american petroleum industry (api) has established the 650 standard, setting minimum requirements for the design, material, construction. Table of content � page:

Shell course design details one foot method(example).

Advance tank has extensive experience with api 650 tanks ranging. Api 650, weld steel tanks for oil storage 2. During tank design, the designer calculates tmin using api 650 and adds. The api specifications address the required thickness of each piece of steel based on the size of the tank being built as well as the welding requirements. So here's the work process: Tank design detailing introduction the api 650 standard is designed to provide the petroleum industry with tanks of adequate safety and reasonable economy for. We have an incredible amount of database from any. This standard does not present or establish a fixed series of allowable tank sizes; Api 650, storage tank, bottom plate, basic weld sequence. The american petroleum industry (api) has established the 650 standard, setting minimum requirements for the design, material, construction. Api 650 large storage tank, bottom plate installation sequence. The standard api 650 covers the design and calculation of the different elements of the tank. 2 tank tag n0 :

7.2.2 fabrication involving welding shall not be sublet to others without the prior approval of the purchaser. Downstream segment api standard 650 eleventh edition, june 2007 addendum 1: 2 tank tag n0 : During construction, each new strake is added to the tank by the sequence of construction steps is illustrated for strakes i and i+1, and is summarized as follows. This standard does not present or establish a fixed series of allowable tank sizes;

Tank design detailing introduction the api 650 standard is designed to provide the petroleum industry with tanks of adequate safety and reasonable economy for.

Tank construction api 650 in hd. Api 650, weld steel tanks for oil storage 2. Welded tanks for oil storage api standard 650 twelfth edition, march 2013 addendum 1, september 2014 addendum 2, january 2016 errata 1, july 2013 errata 2, december 2014 special notes api publications necessarily address problems of a general nature. Api 650 is widely used for tanks that are designed to internal pressures of 2.5 psi or less and store products such as crude oil, gasoline, chemicals and produced water. Inspeksi is one of the best places to find api 650 tank construction sequence documents in pdf and powerpoint formats. During construction, each new strake is added to the tank by the sequence of construction steps is illustrated for strakes i and i+1, and is summarized as follows. These storage tanks operate at 250°f or less with an. Api 650, fuel oil storage tank with dome roof installation sequence. This results in a thinner tmin as compared to the api 650 tmin calcula>on. So here's the work process: 7.2.2 fabrication involving welding shall not be sublet to others without the prior approval of the purchaser. Api 653 has a lower safety factor. In view of the materials of construction, requirements and recommendations are set forth, i.e.:

Welded tanks for oil storage api standard 650 twelfth edition, march 2013 addendum 1, september 2014 addendum 2, january 2016 errata 1, july 2013 errata 2, december 2014 special notes api publications necessarily address problems of a general nature. Api 620 governs the design and construction of large, welded, low pressure storage tanks. Welded tanks for oil storage. Depending on the desired design and design conditions, these tanks are equipped with a conical roof or a doomed roof, with or without anchors and stiffening. This standard does not present or establish a fixed series of allowable tank sizes;

D = normal tank diameter , in feet h = depth of tank , in feet shell design :

Api 650 is the standard governing welded tanks for oil storage. During construction, each new strake is added to the tank by the sequence of construction steps is illustrated for strakes i and i+1, and is summarized as follows. Api standard 650 eleventh edition, june 2007 addendum 1: This results in a thinner tmin as compared to the api 650 tmin calcula>on. Depending on the desired design and design conditions, these tanks are equipped with a conical roof or a doomed roof, with or without anchors and stiffening. In api 650 (welded steel tanks for oil storage ) we usually use lap joint and the examination please refer to para 7.3.3 selama pekerjaannya sudah sesuai sequence saya pikir tidak akan ada masalah. 1 material receiving inspection report. Api 650, fuel oil storage tank with dome roof installation sequence. Api 650 is widely used for tanks that are designed to internal pressures of 2.5 psi or less and store products such as crude oil, gasoline, chemicals and produced water. 7.2.2 fabrication involving welding shall not be sublet to others without the prior approval of the purchaser. We have an incredible amount of database from any. Asme section ix, welding and brazing qualifications. After being laid out and tacked, bottom plates shall be joined by welding the joints in the sequence provided in attachment 2, unless otherwise specified by the engineer.

Komentar

Posting Komentar